Emkhakheni wanamuhla wokuncintisana kakhulu, amasu asebenzayo futhi aqondile we-welding asephenduke isihluthulelo samabhizinisi amaningi ukuze aphishekele ikhwalithi enhle kakhulu nokukhiqiza. Njengomshini wokuguqula izinguquko emisha, umshini we-waser we-laser weldering uphinda usebenzise iphethini yomkhakha we-welding wensimbi ngezinzuzo ezingakaze zibonwe, ziletha inani elingakaze libonwe kanye namathuba ebhizinisi lakho.

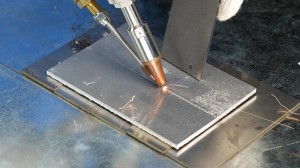

Umshini we-welding we-handheld laser, ngezinto zawo zezobuchwepheshe ezivelele, wenza i-welding ibe lula futhi ibe lula kunangaphambili. Ikwamukela ubuchwepheshe obuthuthukisiwe be-laser futhi ingakhiqiza ugongolo lwe-laser nge-High Energy density, ukuncibilika ngokushesha nokujoyina izinto zensimbi ndawonye. Uma kuqhathaniswa nezindlela ze-welding zendabuko, umshini we-waser we-laser welding awudingi umsebenzi wokulungiselela we-welding we-bumsur Ama-opharetha adinga kuphela ukubamba inhloko eyisibhamu engasindi futhi angakwazi ukwenza ngezifiso imisebenzi ye-welding emisebenzini yensimbi yezinhlaka ezahlukahlukene nosayizi. Noma ngabe ukukhiqizwa ubucwebe obuntekenteke noma umhlangano wezingxenye zemishini emikhulu yezimboni, kungaziphatha kalula, kuthuthukisa kakhulu ukuguquguquka nokuvumelana nezimo nokukhiqizwayo.

Ukucacisa kungenye inzuzo emangalisayo yomshini we-waser we-laser welding. Ukunemba okugxile kakhulu kwe-laser beam kuphakeme kakhulu, kunika amandla okulawulwa okuqondile kwesikhundla se-welding kanye nokujula ukuze aqinisekise ukuthi ukufudumala ngakunye kungahlangabezana nezidingo eziqondile ezingeni le-micromeometer. Lokhu kusho ukuthi ngesikhathi senqubo ye-welding, ngeke kube khona izinkinga zekhwalithi ezinjengokuguquguquka kwe-welding kanye nama-wever weversing, ukunciphisa inqubo yokwenqaba kanye nezinga lokuphehla. Kwezimboni ezinezidingo eziphakeme kakhulu zekhwalithi yomkhiqizo, njenge-aerospace, ukukhiqiza izimoto, kanye namadivayisi wezokwelapha, umshini we-waser welding ngokungangabazeki ngokungangabazeki uyisinqumo esihle sokuqinisekisa ukuqina kanye nokwethenjwa kwekhwalithi yomkhiqizo. Kungasiza amabhizinisi akho akhiqize imikhiqizo eqondile futhi esezingeni eliphakeme futhi athuthukise isithombe somkhiqizo kanye nokuncintisana kwemakethe.

Ngaphezu kokuphumelela futhi okunembile, umshini we-waser we-laser welding futhi unezici ezinhle kakhulu zokonga amandla nezici zokuvikela ezemvelo. Izindlela ze-welding zendabuko zivame ukuhambisana nenani elikhulu lokusebenzisa amandla kanye nokukhishwa kwegesi okuyingozi, ngenkathi umshini we-waser welding we-laser we-welding udinga kuphela ukusebenzisa noma yimaphi amagesi alimazayo futhi avume ukuthuthukiswa kwentuthuko eluhlaza okotshani kanye nemvelo. Lokhu akusizi nje ukunciphisa izindleko zokukhiqiza zamabhizinisi kodwa futhi zenza umnikelo omuhle ekuvikelweni kwemvelo, okwenza ibhizinisi lakho lifeze imithwalo yemfanelo yalo yezenhlalo ngenkathi lithola ukubonwa kanye nokudumisa okuvela kuyo yonke imikhakha yomphakathi.

Ngokuya ngokusebenza, umshini we-waser we-laser welding ubheka ngokugcwele isipiliyoni somsebenzisi. Ifakwe ohlelweni olusebenzayo olusebenzayo, futhi isikhombimsebenzisi sokusebenza silula futhi sinembile. Ngisho nabaqalayo ngaphandle kokuhlangenwe nakho okucebile kwe-welding kungaqala ngokushesha ngesikhathi esifushane. Ngokusebenzisa izilungiselelo zepharamitha yedijithali, abahlinzeki bakwazi kalula ukulungisa amapharamitha anjengamandla we-laser, ijubane le-welding, kanye nemvamisa ye-pulse ngokusho kwezinto ezihlukile ze-welding kanye nezidingo zenqubo ukufezekisa izixazululo ze-welding ezenziwe ngezifiso ezenziwe ngezifiso. Ngaleso sikhathi, umshini we-welding we-waser we-waser we-laser futhi unemisebenzi yokuvikela ukuphepha kokuphepha, efana nezinkinobho zokuvikela ama-laser nezimo eziphuthumayo, eqinisekisa ukuphepha komuntu siqu kwabasebenza kuzo zonke izici futhi kunika amandla i-Enterprise ye-Welding kahle ngaphansi kwesakhiwo sokukhiqizwa okuphephile.

Ukukhetha umshini we-waser welding we-waser welding kusho ukukhetha isisombululo esisebenzayo, esinembile, nesinemvelo sokuxhumeka kwensimbi. Noma ngabe uyibhizinisi elincane lokukhiqiza elisanda kuqala noma ifektri enkulu eyaziwayo embonini, umshini we-waser we-laser welding ungaletha i-acleap emshinini yenqubo yakho futhi akusize uvelele emncintiswaneni wemakethe onolaka. Ithimba lethu lobuchwepheshe lizokunikeza ngokubonisana okuphelele kwangaphambi kokuthengisa, ukusekelwa kokuthengisa, kanye nensizakalo yokuthengisa ngemuva kokuqinisekisa ukuthi awunankinga ngesikhathi sokusetshenziswa komshini we-waser welding we-waser we-Laser Wester.

Unganqikazi isikhathi eside. Xhumana nathi ngokushesha bese uvumela umshini we-welding we-waser welding ube ngumsizi onamandla wokuthuthuka kwebhizinisi lakho. Masivule ngokuhlangene isikhathi esisha sokuxhumeka kwensimbi okusebenzayo futhi okuqondile bese sidala ukusebenza okuhle kakhulu nekusasa!

Isikhathi sePosi: Dec-17-2024