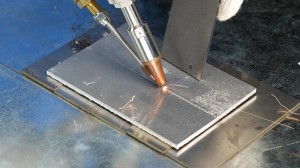

Ekukhiqizeni kwanamuhla, ukusetshenziswa kweI-2000W fiber laser welding imishiniOkwezinsimbi ze-aluminium ziya ngokuya zisaba kakhulu. Kodwa-ke, ukuqinisekisa ikhwalithi nokuphepha kwe-welding, lezi zindaba ezilandelayo ezilandelayo zidinga ukubonwa.

1. Ukwelashwa okungaphezulu ngaphambi kokushiswa

Ifilimu le-oxide ebusweni be-aluminium yensimbi ingayithinta kakhulu ikhwalithi ye-welding. Ukwelashwa komhlaba okuphelele kufanele kwenziwe ukuze kususwe ifilimu le-oxide, amabala e-oyela nokunye ukungcola. Lapho izingxenye ezithile zezimoto zifaka i-aluminium Frame, ngenxa yokunganakwa kokwelashwa komhlaba, inani elikhulu lama-pores kanye nemifantu livele eWeld, kanti izinga lokuqunjelwa liyehla kakhulu. Ngemuva kokwenza ngcono inqubo yokwelashwa, izinga lesiqu likhuphuke ngaphezu kwama-95%.

2. Ukukhetha kwamapharamitha afanelekayo we-welding

Amapharamitha we-Welding anjengamandla we-laser, ijubane le-welding kanye nesikhundla sokugxila kubaluleke kakhulu. Amapuleti e-aluminium anobukhulu obungu-2 - 3mm, amandla ka-1500 - 1800w afaneleke kakhulu; Kulabo abanobukhulu obungu-3 - 5mm, 1800 - 2000w kufanelekile. Ijubane le-welding kufanele lifane namandla. Isibonelo, lapho amandla e-1800W, ijubane elingu-5 - 7mm / s lilungile. Isikhundla sokugxila futhi sithinta umphumela we-welding. Ukugxila kwamapuleti ancanyana kusebusweni, kuyilapho kumapuleti aminyene, kudinga ukujula ngaphakathi.

3. Ukulawulwa kokufakwa kokushisa

I-Aluminium Metal inokuvuka okuphezulu okushisayo futhi ithambekele ekulahlekelweni kokushisa, okuthinta ukungena kwe-weld kanye namandla. Kudingeka ukulawula okuqondile kokufakwa kokushisa. Isibonelo, lapho izingxenye ze-aluminium ze-aerospace zelded aluminium, ukulawulwa kabi kokufakwa kokushisa kwaholela ekuhlanganiseni okungaphelele kwe-weld. Inkinga yaxazululeka ngemuva kokuthola inqubo.

4. Ukusetshenziswa kwegesi evikelekile

Ukuvikela igesi efanelekile kungavimbela i-weld oxidation kanye nokuqina. I-Argon, i-Helium noma izingxube zabo zivame ukusetshenziswa, futhi izinga lokugeleza kanye nokuqondisa okushayayo kufanele kulungiswe kahle. Ucwaningo lukhombisa ukuthi izinga lokugeleza kwe-Argen of 15 - 20 l / min kanye nesiqondisi esifanelekile sokushaya kunganciphisa impasitha.

Esikhathini esizayo, kulindeleke ukuthi amandla aphezulu kanye nemishini yokuqwashisa ye-laser ye-laser ye-laser ehlakaniphile izovela, futhi izinqubo ezintsha ze-welding kanye nezinto zokwakha nazo zizothuthukisa uhlelo lwayo olubanzi. Ekuphetheni, ngokulandela lezi zindlela zokuphepha, ukuqongelela okuhlangenwe nakho nokwandisa inqubo kungenzeka ukuthi izinzuzo ze-laser welding zisetshenziselwe ukuthuthukisa imboni yezokukhiqiza.

Isikhathi sePosi: Jul-12-2024