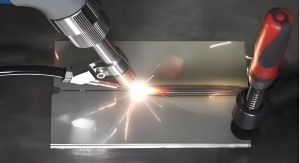

Ensimini yanamuhla ethuthukisiwe yokukhiqiza, TheUmshini we-waser we-waser werheld weldingUba ngukukhetha okuthandwayo we-welding yezimboni ngokusebenza kwayo okuhle nezinzuzo ezibalulekile. Ngakho-ke, yini izinzuzo zayo eziphambene? Ake sihlole.

I. Ukucaciswa kobuchwepheshe amapharamitha akhombisa ukusebenza okuqinile

- Amandla we-Laser: Ibanga elijwayelekile le-laser liphakathi kuka-800w - 2000w, elingahlangabezana nezidingo ze-welding zobukhulu obuhlukile nezinto zokwakha, ukuhlinzeka ngamandla okwanele we-welding ephezulu.

- Ijubane le-Welding: Ijubane layo le-welding lingafinyelela ama-5m / min - 10m / min, elithuthukisa kakhulu ukusebenza kahle kokukhiqiza futhi lifumene umjikelezo wokukhiqiza.

- Ububanzi be-Sport: Ububanzi be-Spot buphakathi kuka-0.2mm - 2mm. Ukulawulwa kwendawo eqondile kungafinyelela amaphuzu amahle futhi aqinile we-welding.

- Imvamisa yokusebenza: Imvamisa yokusebenza yi-20KHZ - 50Khz. Ukusebenza okuvame kakhulu kuqinisekisa ukuqhubeka nokuqina kwenqubo ye-welding.

- Isisindo semishini: Isisindo esingama-20kg - 60kg sinika amandla opharetha ukuba abambe futhi awusebenzise kalula futhi abhekana nezimo ezihlukene zokufudumala.

- Ukucaciswa kobukhulu

- Izidingo Zokufaka Amandla: Imvamisa, isekela okokufaka kwamandla ka-220v noma 380v, ukuzivumelanisa nezindawo eziningi zamandla ezimboni.

- Uhla lwe-Welding Malue of Welding: Ilungele izinto ezahlukahlukene zensimbi ezijwayelekile njengensimbi engenasici, i-carbon yensimbi, i-aluminium alloy, ne-Copper, ukuhlinzeka ngamathuba wohlelo lokusebenza obanzi wemikhakha ehlukahlukene.

- Idatha yokusetshenziswa kwamandla kwemishini: Uma kuqhathaniswa nemishini ye-welding yendabuko, ukusetshenziswa kwayo kwamandla kuncishiswa kakhulu, futhi kungagcina izindleko eziningi zamandla zamabhizinisi ngesikhathi eside.

II. Ithuluzi elinamandla lokuthuthukisa ukusebenza kahle komsebenzi

Le khasiUmshini we-waser we-waser werheld weldingUthuthukise kahle umsebenzi ngokusebenza kwayo okuvelele. Isibonelo, kwibhizinisi lokukhiqiza lezimoto ezisebenzayo, kuthatha amahora amaningi ukuqedela i-welding yengxenye eyinkimbinkimbi ngezindlela zendabuko ze-welding. Kodwa-ke, ngemuva kokuthola umshini we-waser-opholile we-waser welding umshini, isikhathi se-welding sifinyezwa amashumi emizuzu. Isivinini se-welding esisheshayo kanye nekhwalithi ephezulu ye-welding ye-weldising ikhuphule kakhulu izinga lokuphasa kwesikhathi esisodwa futhi inciphise isikhathi nezinsizakusebenza zichithwe ngenxa yokusebenza kabusha.

III. Yehlisa kakhulu izindleko

- Imibandela yokusetshenziswa kwamandla kwamandla, ubuchwepheshe obusebenzayo be-laser kanye nohlelo lokuphathwa kwamandla olwenziwe kahle lwenza umshini we-welding we-waser we-waser we-waser we-waser ube nokusetshenziswa kwamandla okuphansi ngesikhathi sokusebenza, futhi ukusetshenziswa kwesikhathi eside kungagcina izindleko zikagesi eziningana.

- Ngokuya ngezindleko ezibonakalayo, ukulawulwa kwe-welding okuqondile kunciphisa ukulahleka kwezinto ezibonakalayo ngesikhathi senqubo yokufaka i-welding, kuthuthukisa ukusetshenziswa kwezinto ezibonakalayo, futhi kunciphisa izindleko zokuthenga zezinto zokusetshenziswa.

- Izindleko zokulungiswa zincishiswe kakhulu. Ukusebenza kwayo okuzinzile kanye nokwakheka okulula kunciphisa imvamisa nezindleko zokuhluleka kwemishini nokulungiswa.

IV. Ukusebenza okungenakuqhathaniswa ekusebenzeni

- Ukuklanywa kokubukeka kwemishini kungu-ergonomic, isibambo sizizwa sikhululekile, futhi akulula ukukhathala phakathi nokuhlinzwa isikhathi eside.

- Isixhumi esibonakalayo se-Human-computer Confect silula futhi sinembile, futhi izinkinobho zokusebenza zicacile futhi kulula ukuziqonda, ukuvumela abahlinzeki ukuthi baqale ngokushesha.

- I-Intelligent Parameter Ukusetha umsebenzi inika amandla opharetha ukuguqula kalula amapharamitha we-welding ngokwemisebenzi ehlukene ye-welding.

Ekuphetheni,Umshini we-waser we-waser werheld weldingUkhombisile izinzuzo ezibalulekile emkhakheni we-welding wezimboni ngokuchazwa kwayo kobuchwepheshe obunamandla, ukusebenza okusebenzayo okusebenzayo, ukonga izindleko okumangalisayo nezindlela ezisebenzayo zokusebenza. Noma ngabe kuwukuthuthukisa ukusebenza kahle kokukhiqiza, kunciphise izindleko zokukhiqiza, noma unikeze isipiliyoni sokusebenza esikahle, kuyindlela efanelekile. Kukholakala ukuthi ngokuzayo, izodlala indima ebalulekile emasimini amaningi futhi ithuthukise ukuthuthukiswa komkhakha wokwakha.

Isikhathi sePosi: Jul-09-2024